Large reflecting mirrors lie at the heart of the world’s most powerful telescopes that observe distant galaxies, stars and planets. A company formed by University of Hawaiʻi at Mānoa Institute for Astronomy (IfA) scientists and students through UH’s innovation incubator has demonstrated a new way to shape thin mirror surfaces using high-power lasers. These mirrors depend on precise surface shapes that are accurate to just a few millionths of an inch.

Up until now such glass surfaces have been shaped using a slow, painstaking process of repeated grinding and measuring. The newly formed company, MorphOptic Inc., applied for a patent for a much faster, more efficient technique called “curvature polishing” that achieves better mirror surfaces.

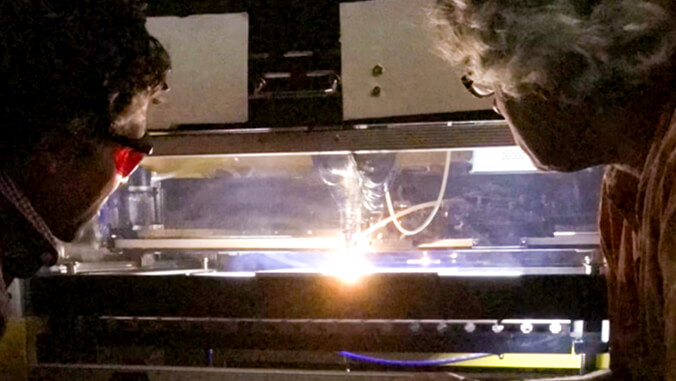

The technology uses a large 3D printer and an industrial CO2 laser to create a highly reflective and curved surface. MorphOptic Inc. has demonstrated it can even shape window glass to create optical-quality mirror surfaces.

“These methods have the potential to decrease the cost and fabrication time of mirrors as big as five meters across by a factor of 10 or more,” explained MorphOptic CEO and IfA Astronomer Jeff Kuhn.

The company’s process generates thin mirrors with an ultra-smooth reflective surface that can preserve the focusing power of a mirror without scattering the incident light.

“We hope to develop this novel technology to create a unique manufacturing capability and in so doing, support job growth and also establish a new ‘green’ high tech industry unique to Hawaiʻi,” said IfA Scientist Joe Ritter, who founded MorphOptic.

The company expects the first communication-industry mirrors to be completed within 12 months. UH is a co-owner of this new technology. The UH Office of Innovation and Commercialization will also play a leading role in its patenting and commercialization efforts.